Since 1971, Taurus has been in the business of providing products and services custom designed to meet the electrical and environmental protection requirements of our customers’ ESP applications.

Over the past 50 years, we have grown significantly and our facilities now sit on over 60,000 sq ft across 3 campuses. Our main location, in Long Beach CA, is home to our Head Office, Applications, Design Engineering, Manufacturing and Testing divisions. Housing these divisions in close proximity fosters an excellent environment for interdisciplinary development, collaboration and innovation.

Our Legacy

50 YEARS OF OIL FIELD SERVICE

We have succeeded in the Artificial Lift industry because of our customer service mindset and rapid response times. Together with our custom design capabilities and engineering solutions, we have expanded from providing equipment to the Southern California oil field to major geomarkets around the world.

In House Manufacturing / Fabrication

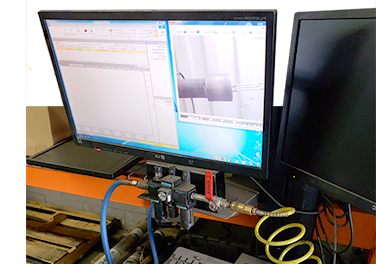

Our Long Beach facility manufactures and tests all products in house.

We hold a wide variety of bespoke manufacturing and testing equipment ranging from our state-of-the-art Compression and Injection presses to our high pressure test facility. Products are serialized, with parts and materials having various levels of hard or soft traceability. Progress is tracked, from forecast through manufacture and to customer billing, using a proprietary software encompassing SAGE CRM, ERP and MRP, allowing for on and off-site status updates, review and quality tracking. Following strict manufacturing procedures, quality control documentation and continuous process improvement Taurus continues to meet and exceed customer expectations.

Innovative Designs

Our dedicated Engineering teams provide customers individualized, custom solutions and support.

Both customer driven projects and internal research and development are carried out by these teams, using 3-D Solid Modeling and Finite Element Analysis software to design and test our products. Taurus holds a high wealth and breadth of knowledge and experience; our Director of Engineering and CEO alone, have over 75 years of experience in the oil industry.

Quality Program

Through vendor verifications, 100% critical dimension inspections and material specifications all of our products adhere to stringent quality checks and comply with NACE MR0175/ISO 15156 (where applicable).

Our designs undergo pressure and electrical tests well beyond industry norms. In addition to acceptance and factory testing, final product electrical testing is carried out on each and every electrical component before shipping. All electrical tests are performed under strict Taurus safety standards and testing criteria per API 11S6, CSA 6238-81, IEEE 400/1017/1018/1019, and IEC 60502, where applicable. All inspection and testing equipment is professionally maintained and 3rd party calibrated to ensure accuracy and continued safety of our employees and products.

Taurus Engineering, Inc. (TEI)

1335 W. Cowles Street

Long Beach, CA 90813

Fax: (562) 437-4774

techsupport@taurusengineering.com

sales@taurusengineering.com

Customer Service / Orders

cstei@taurusengineering.com

(562) 760-0166

1320 W. 15th St.

Long Beach, CA 90813

Taurus Engineering and Control (TEC)

CERTIFICATION

Taurus Engineering offers a selection of products that have been Third-Party tested and certified to worldwide specifications for Hazardous Locations, including the National Electrical Code (CSA: US & CANADA), ATEX and IEC.

Taurus Engineering is committed to manufacturing high quality products and is an ISO 9001:2015 certified company